H- beam laser cutting machine

For H beam cutting, Marking.

12KW-40KW source

Up to 1meter width H beam cutting

For H beam cutting, Marking.

12KW-40KW source

Up to 1meter width H beam cutting

We have customers from all over the world and have been cooperating for over 10 years. Thank you for choosing HoneybeeCNC.

Whether you want to use it yourself or as a local agent, we are your most reliable partner.

Please leave your contact information so that we can serve you better.

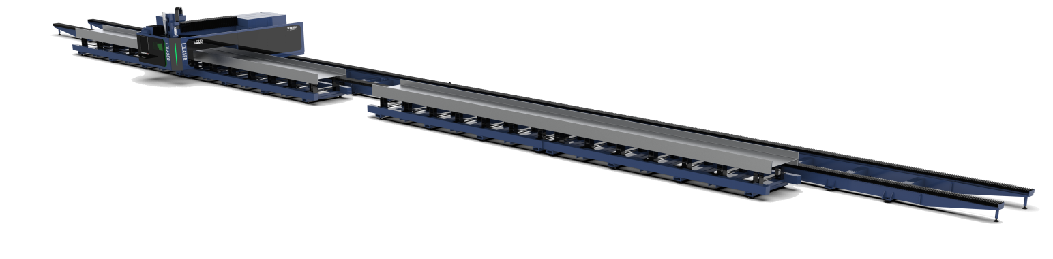

Max 1m width H beam cutting.

max 18m H beam cutting.

With 2 working table.

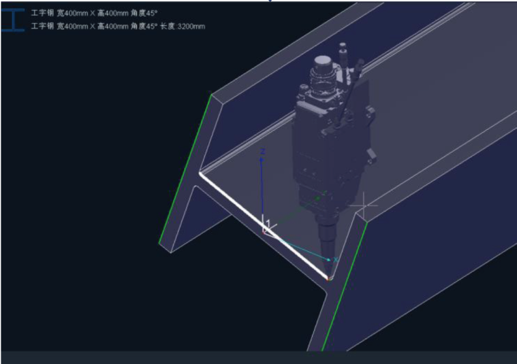

Straight Laser Cutting, Bevel cutting and Marking.

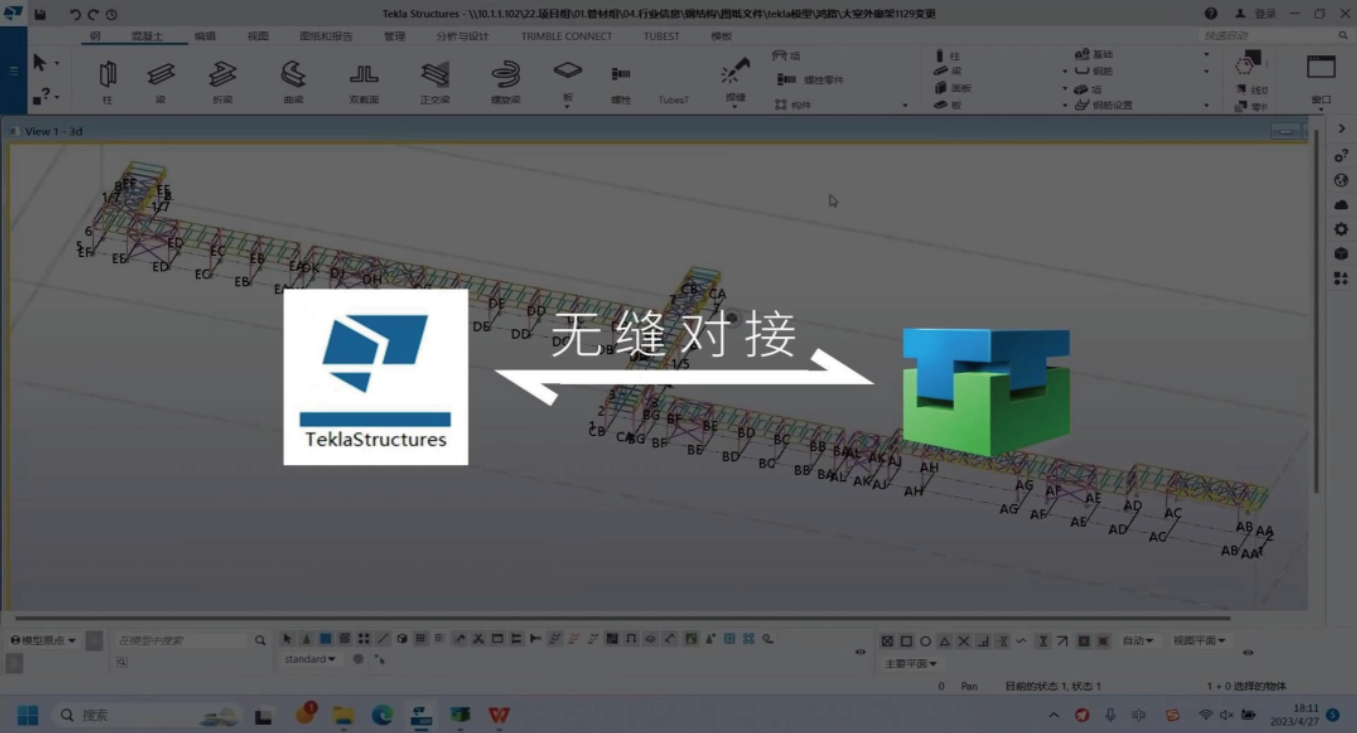

This H series laser is our large-scale H-shaped steel laser cutting machine, which uses advanced laser technology for three-dimensional cutting and drilling. The laser beam generated by the laser source is accurately positioned and controlled through a high-speed scanning system and a CNC system, and can cut and drill holes on three sides of the H-shaped steel. The entire process is precisely controlled by a computer control system to ensure the accuracy of the position, size and shape of cutting and punching. It has has been widely used in steel structure, shipbuilding, automobile manufacturing, construction machinery and other fields. For example, in steel structure production, H-beam laser large-scale cutting machines can be used to process H-beams of various sizes and shapes to meet the requirements of different structures.

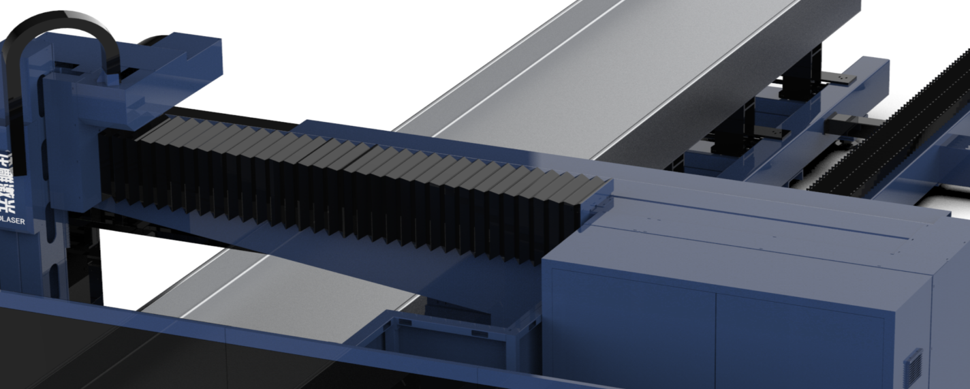

The bed body is formed through multiple processes such as welding, heat treatment, rough processing, precision processing, and spray painting. Adopting a gear rack transmission form to ensure the longitudinal feed accuracy requirements of the machine.

The crossbeam adopts a welded structure, which undergoes rough processing after annealing to eliminate internal stress, and is precision processed after secondary vibration caused by aging treatment, effectively solving the stress by welding and processing, thereby greatly improving the stability of the machine.

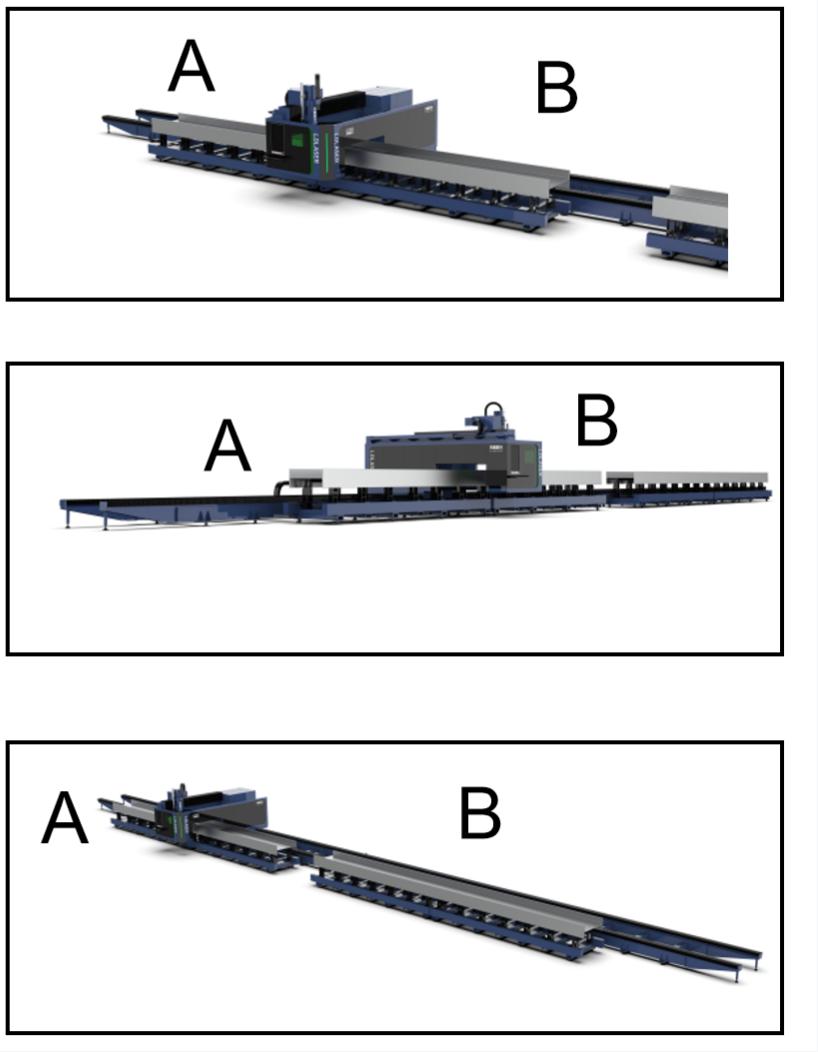

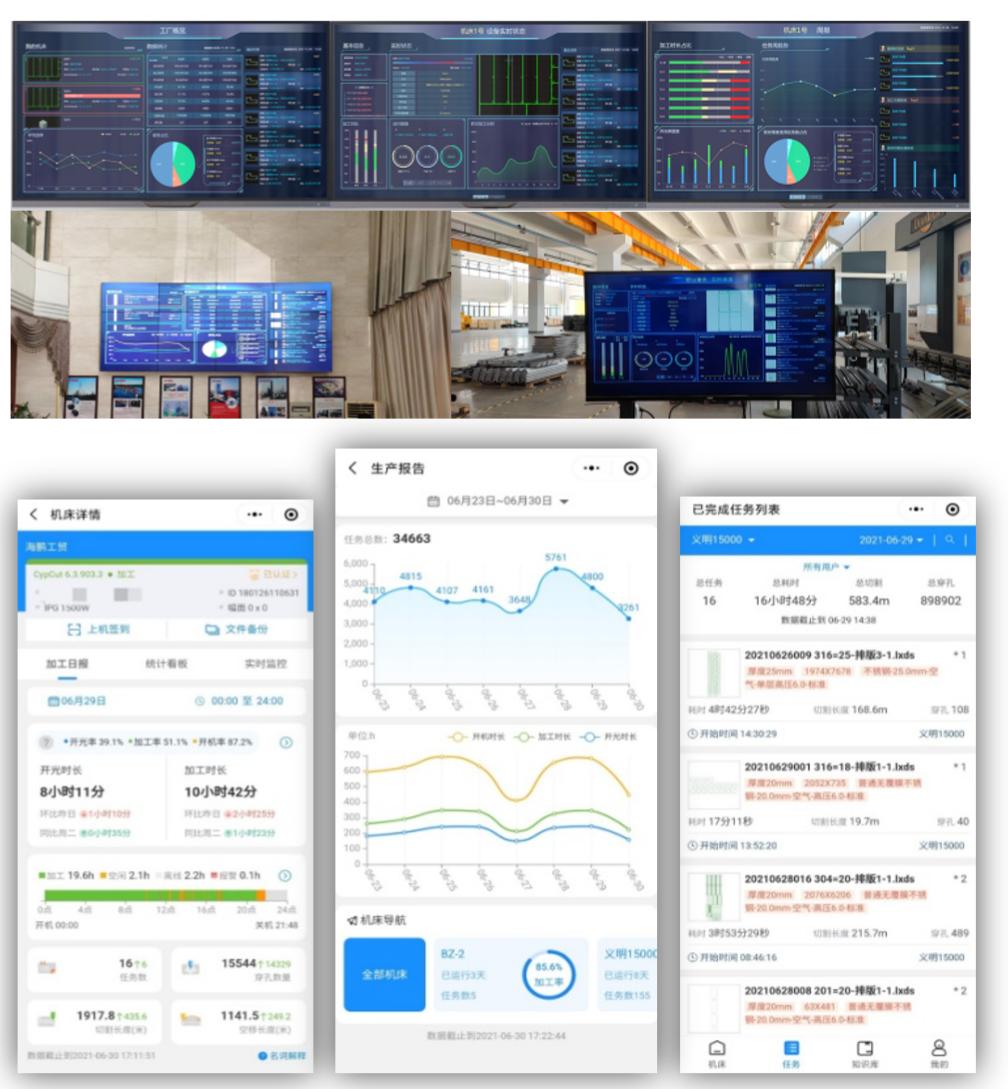

1.Two 12 meter H-beams can be loaded simultaneously, and the laser first processes them in Zone A. After processing, the gantry moves to Zone B

2.Wait for processing to be completed after unloading and loading in Zone A; The gantry is being processed in Zone B, waiting for Zone B processing to be completed

3.After processing in Zone B, the material is loaded and the gantry moves to Zone A for processing, achieving efficient processing without stopping the machine.

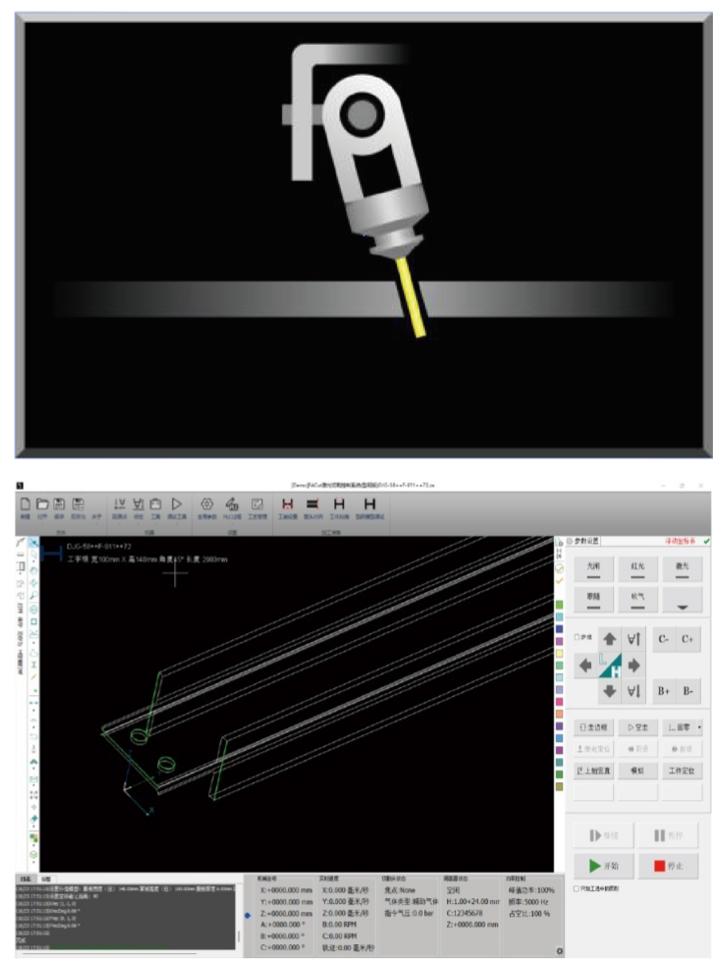

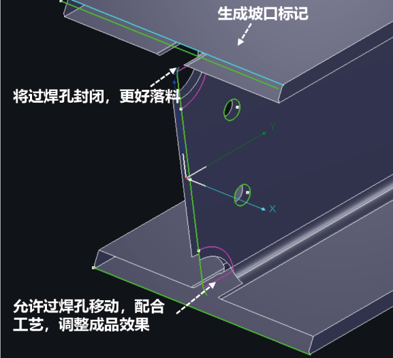

The Bochu H-beam cutting system adopts a combination of visual coarse positioning and visual fine positioning. The BCW contour scanner is used to measure and compensate for the deviation between the steel workpiece and the drawing in real time, ensuring processing accuracy and stability, and avoiding cutting misalignment and head collision problems caused by inconsistency between the drawing and the actual workpiece.

The circular nesting material launched by Baichu Electronics can reasonably cut off parts, weld short materials together as a long part, and fully utilize tailings!

| Model | H5 |

| Dimensions | 30000mm*4800mm*3000mm |

| Laser Power | 30000W |

| Processing range | 150mm≤h≤1000mm 100mmsb≤400mm |

| X-axis maximum travel | ≥1500mm |

| Y -axis maximum travel | ≥25000mm |

| Z- axis maximum travel | 400mm |

| Total equipment power KW

( 20KW Air cutting ) |

170KW/H |

| Phase | 3 |

| Power supply rated voltage | 380V |

| Frequency | 50Hz |

| Overall power protection level | IP54 |